In our topic hub on the future of shipping, we’re asking how self-adaptive materials will affect the nature of cargo.

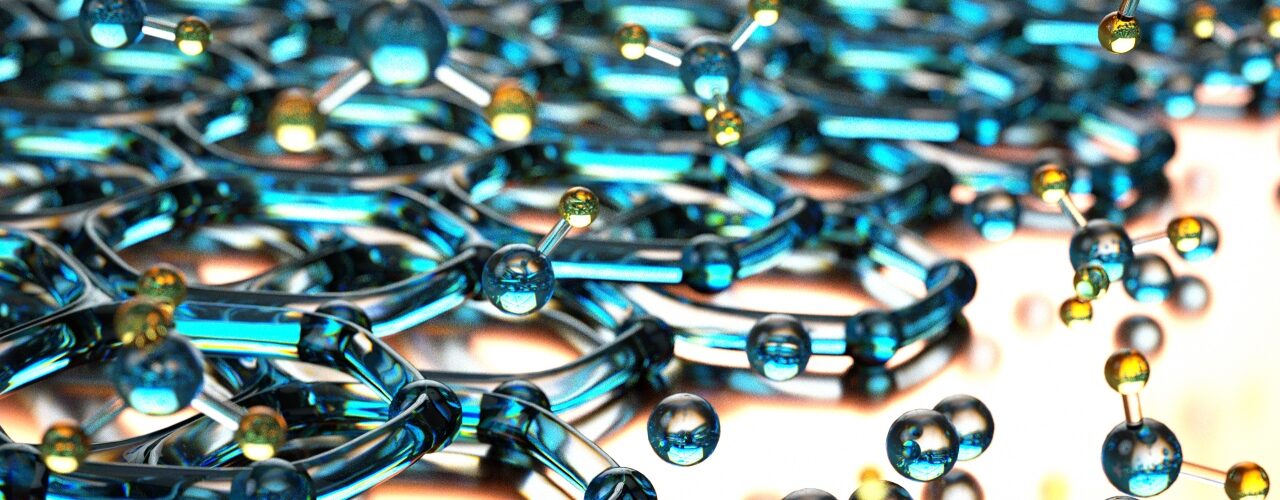

MIT’s Self-Assembly Lab has developed materials that can be programmed to transform their shape autonomously.

The materials range from flexible carbon fibre and hybrid plastics to wood grains and textiles. As Skylar Tibbits, Director of the Lab, explains, “The way we build our structures has become increasingly sophisticated, but the materials we build them from are static, waiting for us to fit them to the required shape.”

Coined ‘4D printing’, where 3D-printed material changes shape over time, the technology opens up a world of possibilities, potentially allowing buildings, infrastructure and equipment to continuously adapt to our use, and to the environment around them. These ‘smart’ materials would respond to daily wear and tear as does skin, healing itself, and so minimising the need for repair. They could also be programmed to learn new material behaviours, befitting different purposes.