Researchers of the Norwegian University of Science and Technology (NTNU) in Trondheim are testing a technique to reduce pollutants from ship exhaust emissions in a pilot project funded by the Research Council of Norway’s Innovation Programme MAROFF (Maritime activities and offshore operations). The team applies a hybrid solution called Lynx Separator which originally was developed for the oil and gas industry. As wet gas runs through the separator, a tabular metal ‘sponge’ spins quickly and removes droplets from gas streams using centrifugal forces. The sponge separates the liquid from the gas and moves it aside and downward, enabling dry gas to stream up.

The method was designed by InnSep AS, a spinout from the Department of Energy and Process Engineering at NTNU, incorporated to engineer a scalable and flexible gas/liquid separator. As yet, separators used in the oil and gas industry are costly and bulky. Previous full-scale laboratory testing performed in Colorado, USA, on a converted missile launch base from the Cold War has been very promising. Sondre K. Jacobsen, CEO of InnSep AS, says: “The results there were so good that we managed to convince Statoil, and so now we’re part of DEMO2000, which is a qualification program for new solutions in oil and gas technology”.

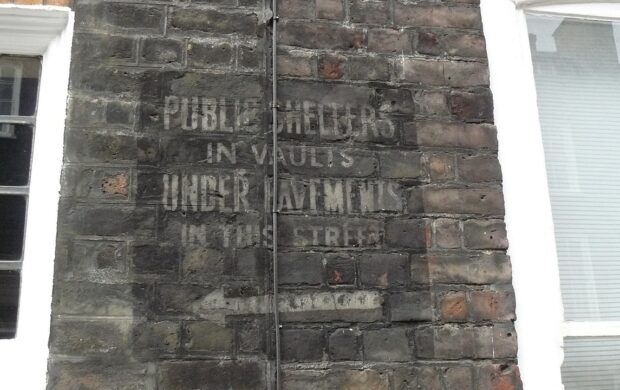

Image Credit: MaxGag / flickr