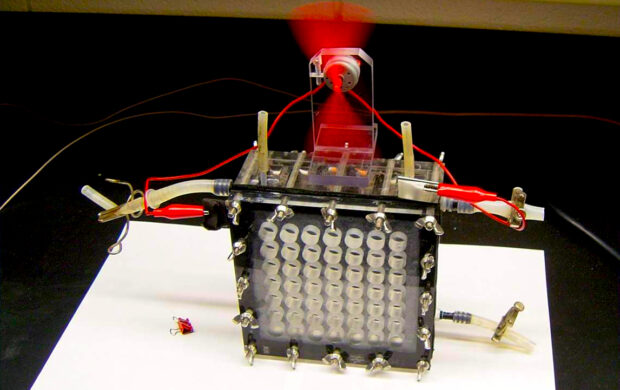

Seeking to demonstrate Iron as a circular fuel source, Dutch students applied their theory to a brewery in the Netherlands. The researchers combusted finely ground iron powder by adding oxygen, which produced heat and rust – the only emissions of the process. Then, using renewable energy they converted the rust back into iron via electrolysis. Given the availability of renewable energy for electrolysis, the entire process was carbon free.

So what?

Given the availability of renewable energy and a suitable industrial application, using iron as a emission-free heat and energy source shows major potential for impact. As iron is one of the cheapest and most abundant metals on Earth, application of this method could have a significant impact on industrial manufacturing.

Whether or not the process is economically viable, solves industrial energy needs best, or is feasible at scale remains to be seen. If this process were to be deployed at scale, what resources might be required to achieve it, and what ramifications would it have on industrial manufacturing? Could we see iron-rich countries orienting their economies around industry?

Join discussion