In our topic hub on the future of shipping, we’re asking how nanomaterials in mainstream manufacturing will affect the nature of cargo.

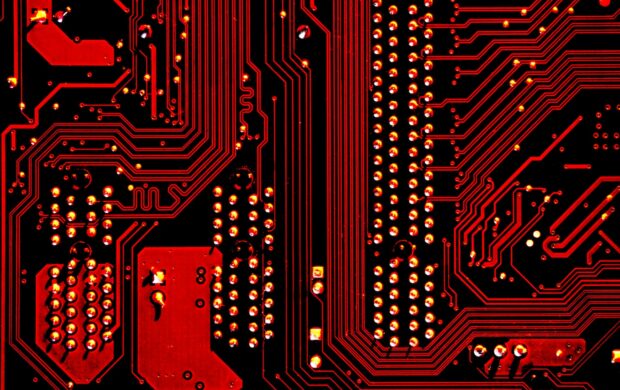

Nanomaterials – a term describing those materials, organic or synthetic, in which a single unit is usually sized between 1 and 100 nanometers (nm) – are typically lighter and stronger, perform better at extreme temperatures, and provide better insulation than their counterparts. For example, Buckypaper, a thin sheet made of carbon nanotubes, is one tenth the weight of steel but potentially 500 times as strong. Already, nanomaterials are used in a variety of ways in the aviation industry, mostly as fillers and coatings, where the weight to strength ratio of materials is particularly important.

As the commercial and sustainability benefits of nanomaterials gain traction, there have been calls for greater material standardisation, transparent pricing and security of supply to enable more widespread use of these materials in mainstream manufacturing. Players from across the electronics, medical, construction and marine industries are experimenting with the use of nanomaterials. As an early example, Zyvex Marine has manufactured a prototype craft using composite non-enhanced carbon fibre. Zyvex reported a 75% reduction in fuel consumption costs, translating to increased range and lower operating cost.

Image credit: Brookhaven National Laboratory